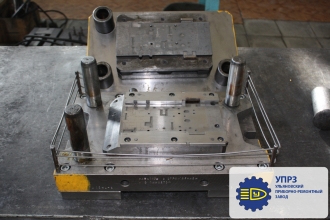

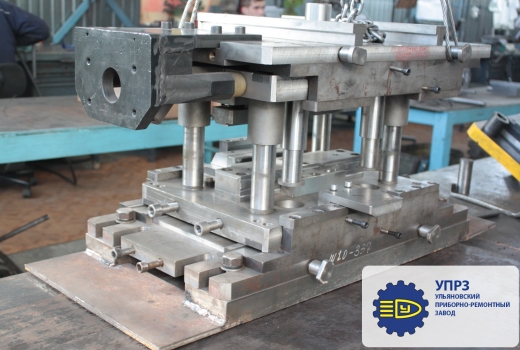

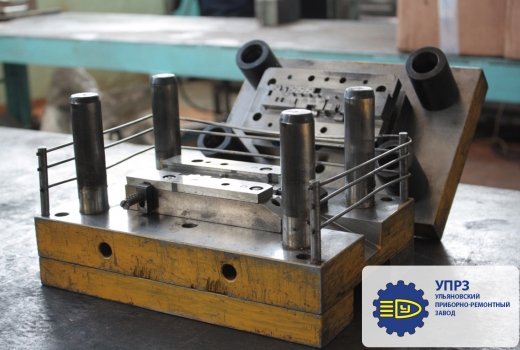

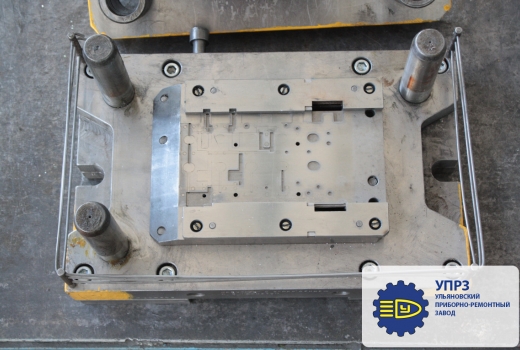

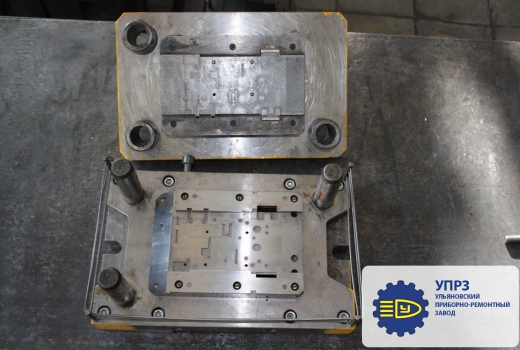

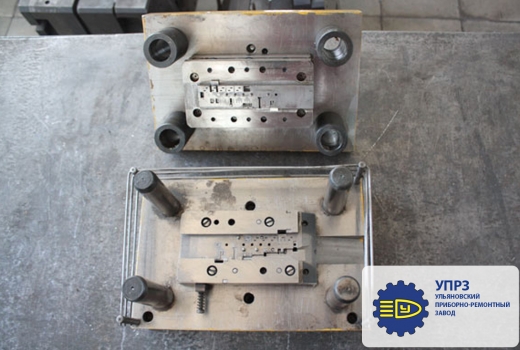

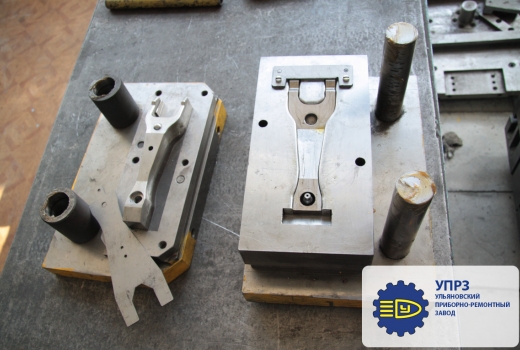

Manufacture and forming of parts by cold stamping using various dies is a simpler and, correspondingly, less expensive method of processing materials. It has some cons, but there are certain pros in comparison with using molds. Manufacture of cold stamping dies is preceded by preparation of the manufacturing cycle plan, with allowance made for a number of mandatory provisions and factors at all its stages. From design up to complete operation analysis our specialists at tool-making facilities will be monitoring quality and timing of the parts manufactured.

According to the application, it is possible to distinguish the following types of cold stamping dies:

- Progressive dies;

- Hard-alloy dies;

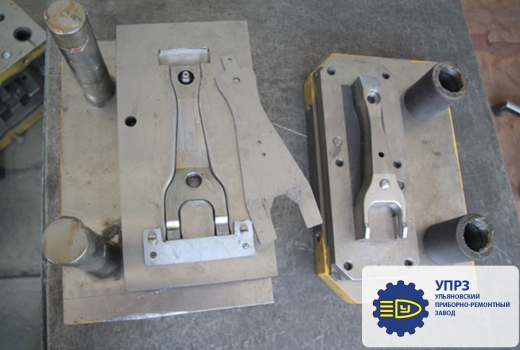

- Shear, punch and double-action (compound) dies;

- Molding and drawing dies;

- Bending dies;

- Quenching dies;

- Twisting and curling dies;

- Assembly and pressing dies.

In the production of various metal products by cold stamping, it is the die that is the most important item that determines the quality of the final product. Therefore, the strictest requirements of the manufacturing cycle must be observed in the cold punching process.

Manufacturers of metal products, for whom stamps are the prime manufacturing tool, do impose very high requirements on them, which we are able to fulfill. The fundamental requirements are as follows:

- High quality of products;

- High performance;

- High reliability;

- Lengthy service life (up to 700,000 punches).

We guarantee our customers high quality characteristics of parts manufactured by means of dies.

Manufacturing Advantages of Cold Punching

Die is much faster to pass the full manufacturing cycle from drafting to getting the finished batch of products. In addition, die stamping is much cheaper than using other methods of manufacturing parts. And all of them are interchangeable - it is very easy to re-punch an item that had already been punched earlier with almost no additional costs. Furthermore, it is possible to create preforms in advance by cold punching for future welding, soldering or machining. There are two types of operations that are performed in the manufacture of cold punching dies:

- Separating - separation of unnecessary fragments from the preform by cold punching;

- Shaping - changing the shape of the preform by plastic deformation. This process eliminates material destruction and heating.

These operations are often combined to reduce the time costs for manufacture and increase the efficiency.