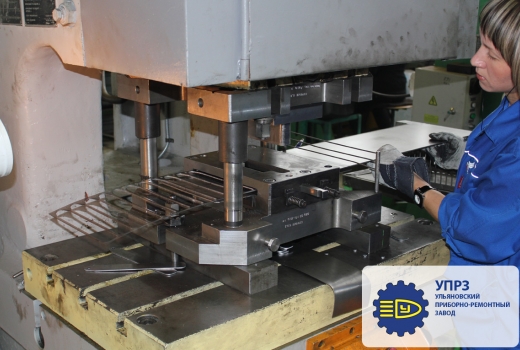

Die stamping site is situated on the floor space of 900 square meters. Main production equipment of 30 units is operated by 12 specialists.

This site is used to create: inserts used for die casting, UAZ series car components and also contacts for lighting units and electric units.

Products are stamped in two ways: automatic and double-handed. Piercing dies on the automated press and progressive dies are automatic. All the other dies are double-handed.

Cold stamping is done using metal sheets 0.3-6 mm in width; pressing force in this process can reach about 160 tons.