The total area of the plastic products shop is about 1,100 sq, m, it is equipped with reliable and high-quality imported equipment ("Arburg", "Battenfeld" and "ENGEL" - Germany, "Bole" and "NEW HAITAI" - China) in the number of about 30 items operated and maintained by 30 employees.

Automatic molding machines (AMM) process a variety of polymeric materials, namely: castable polyurethanes (Desmopan), polycarbonates (Macrolon), polyamides, polymethylmethacrylates (Dacryl), ABS plastics, polyformaldehydes (Kepital, Kocetal), polyolefins and various combinations of the above materials with others, where thermoplastics can be mixed in the shop.

The shop's staff composition includes well-trained employees of the following specialties:

- Adjusters;

- Founders;

- Servicemen;

- Managers;

- Electricians;

- Electronics engineers;

- Quality technicians.

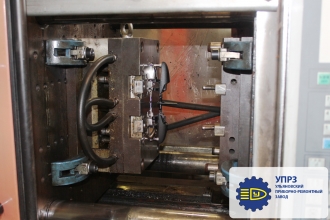

Shop equipment is partly produced by the plant's tool shop (molds, dies). Finished plastic products are fabricated for further sale, as well as used for the company's own needs. For plastics casting either customer or factory supplied molds can be used, which are mounted on automatic molding machines. AMM fleet is constantly updated and expanded, involving today's cost-efficient state-of-the-art high-performance machines with injection volume up to 2000 cu cm and clamping force 60 to 400 tons.

We have the necessary equipment (AMM) and expertise in two-component casting. Today, the company produces spreaders for automotive lighting fixtures.

Our company uses all kinds of polymeric materials such as polycarbonates, polyamides, polyformaldehydes and many other.