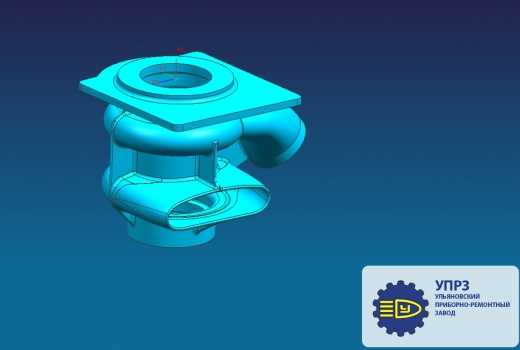

Investment casting is most often used in the production of thin-walled odd-shaped castings both in mechanical engineering and art industry. This is one of the oldest casting methods for manufacture of statues, bells, cannons. A characteristic feature of this type of casting is that each pattern can be used for one casting only as it undergoes sweating in the course of mold production, and the molding sand mixture itself is made not from a homogeneous molten metal, but from the refractory fine dusty material in the binder solution. It is the mixture design that contributes to obtaining castings with high surface quality. The precision of the pattern impress is provided by increased metal temperature, thus investment and binder materials should have a high fire resistance. The con of this method is a long and lengthy casting manufacturing process, which requires tailor-made expensive tooling and highly trained and qualified specialists.

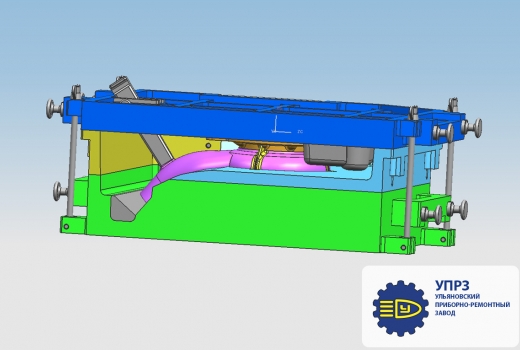

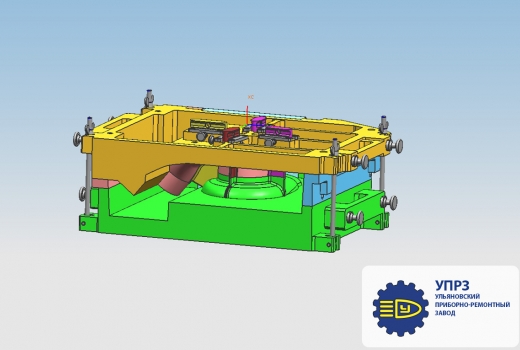

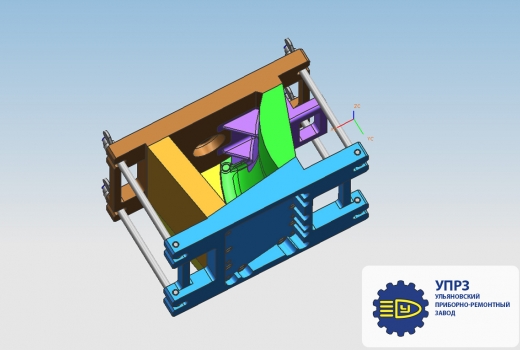

This type of casting is used for the casting of ferrous and non-ferrous metals and alloys. The mold design is very diverse and differs according to the planned potential output and equipment, on which tooling will be operated.

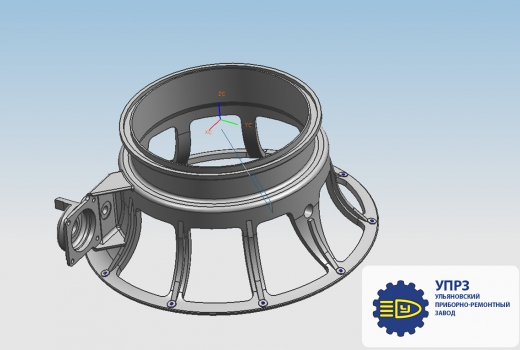

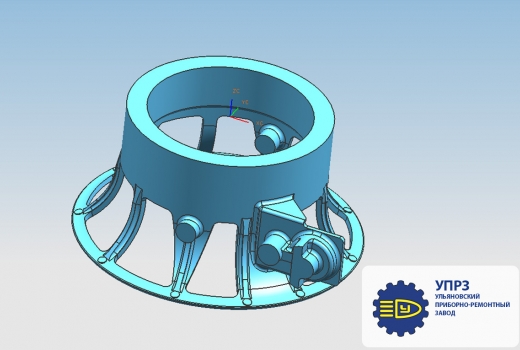

In mechanical engineering, wax casting patterns are made in plaster, plastic and metal molds; the manufacturing process is usually power-actuated and computer-aided. The investment casting method produces parts for aeronautic, instrument-making, mechanical engineering and some other industries utilizing casting techniques involving difficult-to-machine, heat-resistant and corrosion-resistant alloys.

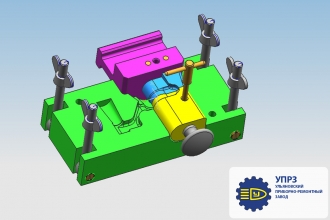

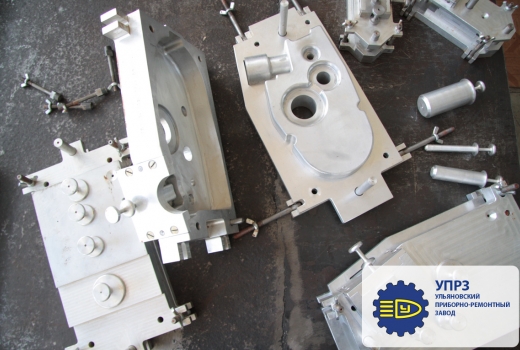

Investment casting tooling disassembly can be power-actuated (designs are similar to molds for pressure casting) and manual (structurally more diverse and produce more castings with more sophisticated geometry). If the product requires a high degree of accuracy, strength and leak-tightness, aluminum castings of said casting type are more preferable than pressure castings. Investment ferrous metal casting produces more precise and beautiful items as opposed to sand casting. Our company can fulfill any order for the design and manufacture of equipment for investment casting, including with reference to the customer's equipment.