Metal casting is the process of manufacturing preforms or finished products, implying the filling of a mold with a liquid material for the purpose of its solidification. Metal casting process utilizes molds or chill molds for pouring-in and cooling of metal.

Ulyanovskiy Priboro-Remontniy Zavod has two types of metal casting:

- Pressure casting;

- Chill (die) casting;

Casting of alloys based on metals of two types:

- Aluminum based alloys;

- Zinc based alloys.

Metal casting process takes place at nonferrous casting site using casting machines with locking force ranging from 1,600 to 2,500 kN.

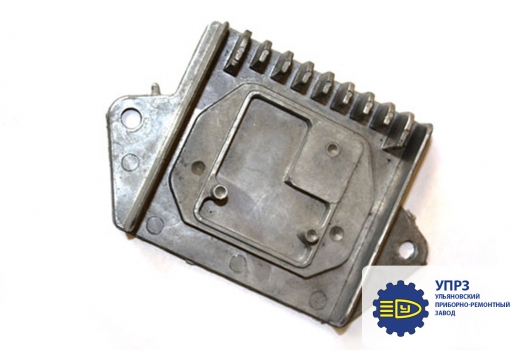

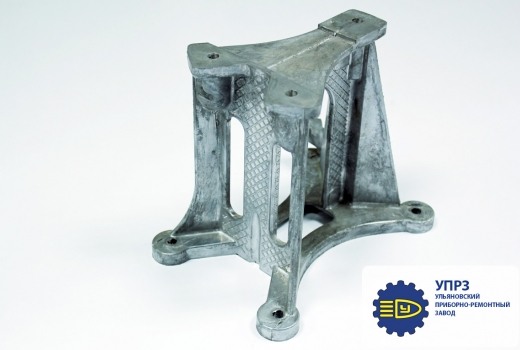

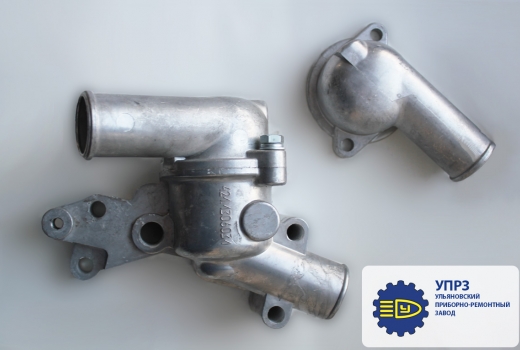

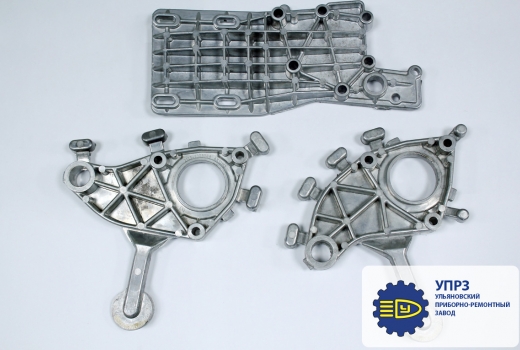

Depending on the design of casting molds from aluminum and zinc alloys, pressure casting produces castings of various complexity, a variety of textures and configurations. We use high-quality certified materials in industry, which are selected not only as per the customer's design documentation, but first of all based on functional operational specifications for parts (aluminum AK 5-AK 12, zinc ЦАМ4-1).

Our raw material suppliers for metal casting and foundry production generally produce alloys that meet the requirements of GOST and have permits for their further sale. For metal processing and removal of foreign matter Ulyanovskiy Priboro-Remontniy Zavod uses dedicated state-of-the-art preparations, with professional lubricants used for serviceability and sound performance of molds.

We have established long-term cooperation with companies specializing in the pressure casting of metals and having an extensive fleet of casting machines with horizontal and vertical casting chambers and locking force of up to 6,000 kN. This allows us to manufacture products of various degree of complexity, size and weight (up to 10 kg) by means of molds for pressure casting of metals.

The corporate tool shop at Ulyanovskiy Priboro-Remontniy Zavod with cutting edge equipment provides quick and high-quality implementation of preventive and planned maintenance of molds while in operation. This allows to significantly increase service life of tooling.

Casting of metals from aluminum and zinc alloys is the most popular type of non-ferrous metal casting used in various industries, including automotive.