Professional workmanship of molds for casting of plastics and other polymeric materials is a complex process involving observance of a variety of process requirements. Production of these high-precision units requires a wealth of experience of engineering and technical specialists, expertise in CAD/CAM applications and dedicated cutting edge equipment for performing all the necessary operations for manufacture of molds, dies and other tooling.

Construction of Molds for Your Needs

The quality of injection molding, its accuracy and durability mean the world to customers since they determine the quality characteristics of finished products. Therefore, the requirements for the mold construction process and capabilities of the molds themselves are quite high, namely:

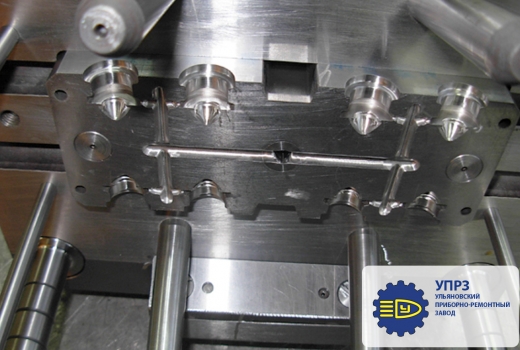

- High reliability of molds;

- High performance (at least 5-10 seconds);

- High quality of products;

- Great operational life.

These requirements can only be fulfilled provided the following conditions are met on site:

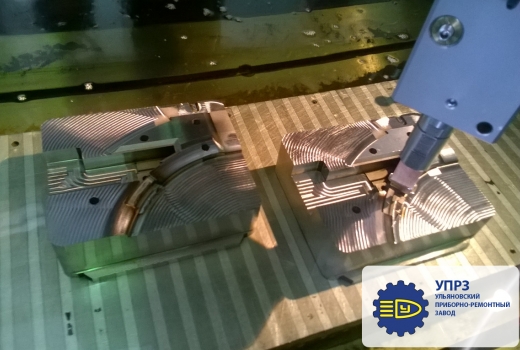

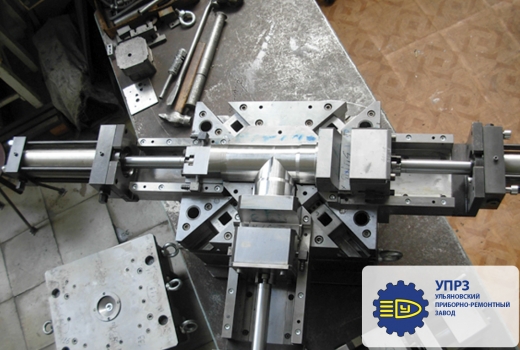

- Sound design solutions;

- Detailed operation analysis;

- High-precision manufacture.

In order to make back an intrinsic value and at the same time generate profits for your company, casting olds should be reliable, have a long service life and a high thermal stability threshold.

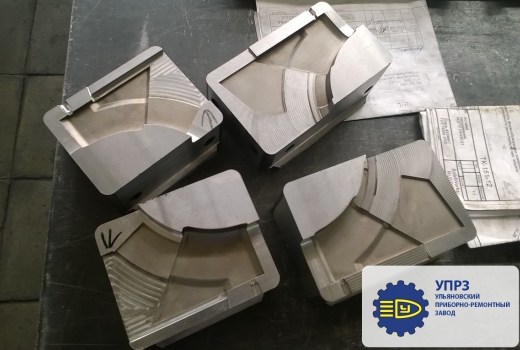

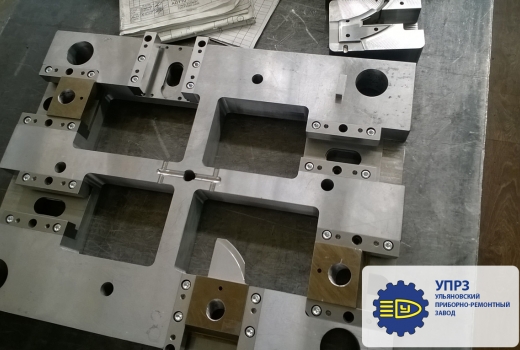

It is these units that we manufacture at the tool shop to gladly offer to our customers. All technical stages in the manufacture of molds for molding of plastics are undertaken by our specialists. They will professionally perform all the necessary engineering development and guarantee split-hair accuracy of the manufacturing process.

Plant Operation and Customer Interaction

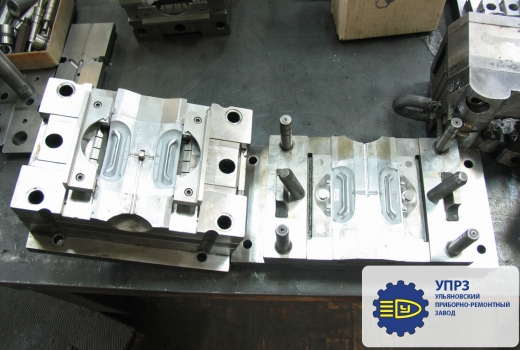

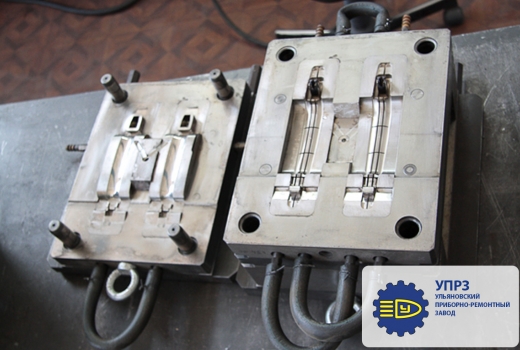

Ulyanovskiy Priboro-Remontniy Zavod specializes in designing and manufacturing complex and high-precision casting molds with the following parameters: weight up to 5000 kg, overall dimensions up to 1000x1000 mm. These parameters are used for technological output of products of various materials by injection molding. Plastics, zinc and aluminum alloys are most often used for such products.

Ulyanovskiy Priboro-Remontniy Zavod has all the necessary skills, pool of experience and capacities to manufacture molds of increased complexity for injection molding of plastics.

Once contract is concluded with the customer, specialists of our plant will perform the following work on the manufacture and provision of technical equipment and documentation for tooling:

- Design and manufacture of molds;

- Creation of item design in accordance with specifications;

- Drawing of the part following the pattern provided by the customer;

- Creation of a three-dimensional part model;

- Production of tooling (dies, molds);

- Production of parts using the customer's tooling or factory based equipment.

Ulyanovskiy Priboro-Remontniy Zavod's long-term hands-on experience allows to fulfill orders for the manufacture of high-quality molds of any complexity in a short span of time at the unbeatable market prices. The secret of our quote is not in cost savings in materials and manufacturing quality. We provide the best available rate for the manufacture of molds because we have managed to precisely adjust all economic and technical processes. In addition, while working with our plant, you will not have to expect a lengthy shipment of parts once they are ready and pay over the odds for customs clearance of freight. You will receive the ready-made items once the order is fulfilled.

All stages of design and manufacture of molds are subject to tight control. The plant also provides a service for selecting the appropriate accessory equipment. Before starting, the project will obligatorily be negotiated with the customer. In the course of its fulfillment we are open to whatever communication and will gladly give ear to your suggestions and requirements.