Ulyanovskiy Priboro-Remontniy Zavod is a complex high-quality production that guarantees a comprehensive approach to addressing your business problems. Business development requires individual attention to everything: from top management to hiring junior service staff. Therefore, search for partners, who are able to assume responsibility for production at a certain level, is an important matter. Our production facilities are very close to customers, as a result, the timing of fulfillment and delivery of orders for molding of plastics are kept to the minimum. A wealth of experience in dedicated operations related to molding of plastics allows us to confidently undertake the implementation of any of your proposals.

Entrust Molding of Plastics to Professionals

Manufacture of products from thermoplastic materials (injection molding of plastics) is a process of increased complexity. One defective part of the total cycle is enough to seriously compromise the quality of the final product. Therefore, proper allowance must be made for each and every factor of multiple-level manufacture as early as prior to operation.

Engineers work out the shape and design features of the desired part in detail so that to exclude an intrinsic flaw due to design error. Raw materials for work can be selected by the customer at its sole discretion, but we always remind that only high-quality raw materials can produce best parts. Casting molds are set for each work on an individual basis, with special focus on this part of the work, ie characteristics of injection molding machines and injection process in general.

We do not save on quality of materials or products. The secret of our affordable prices is in efficient technical and economically viable production organization and ongoing development of the cycle.

Injection molding of plastics is an elaborated way of manufacturing products from thermoplastics. Its main advantage over other similar methods is the rate of finished-product output. The performance of the casting process is 20-30 times higher than the pressing performance, so injection molding of plastics is one of the primary ways of processing plastics in products.

In order to obtain high-quality products from thermoplastics, it is necessary to make allowance for a number of important factors in manufacture:

- Injection molding machine

- Casting mold

- Casting process

- Product design

- Material

In the geometry of the part being manufactured the following factors have a role to play such as wall thickness and its distribution, length and cross-section of the sprue channels. The performance characteristics of the future product are affected by cooling conditions, internal stress and orientation, as well as surface defects such as junction lines.

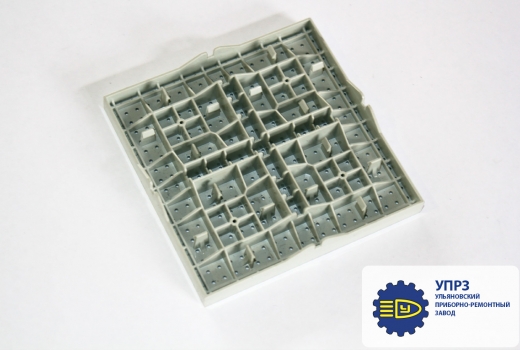

Molding of plastics at Ulyanovskiy Priboro-Remontniy Zavod is carried out using equipment from leading foreign manufacturers such as: "Battenfeld" (Germany), "Arburg" (Germany), "Bole" (China), ENGEL (Austria). Automatic molding machines process a wide range of thermoplastic materials and compositions thereof. Injection molding machines with a clamping force of 60 to 400 ton-force and an injection volume up to 1500 cm³ are available. We have the necessary equipment (AMM) and expertise in two-component casting. Today, the company produces spreaders for automotive lighting fixtures.

In our plastics molding shop we manufacture products for household and technical use, mechanical engineering, radio and electrical engineering, non-food consumer packaged goods, parts for instrument-making and automotive industries.

We not only provide equipment for contracts and orders. If requested, you can order molds at Ulyanovskiy Priboro-Remontniy Zavod for self-manufacture of products