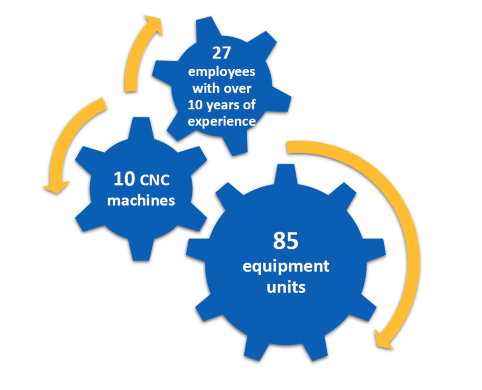

Total floor space of the tool shop of Ulyanovskiy Priboro-Remontniy Zavod is about 2000 square meters. Primary production equipment of more than 80 units is operated by about 60 specialists.

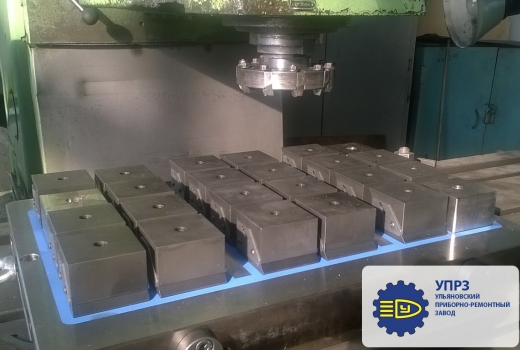

Primary specialty of the shop – making production tools: production of mold for injection molding of plastics, dies for cold stamping and casting tools for casting in metal, aluminum and zinc alloys of high difficulty and precision, sizes up to 1000*1000 mm and weight of up to 5000 kg. The shot also makes accessories, equipment replacement parts and other products.

Specialists, working in the engineering department have extensive experience in the area of engineering production tools for further in-house production. Documentation for molds and dies is always coordinated with the client and undergoes technological analysis. At this stage, the engineers create programs for machining of details and design special production tools and secondary equipment.

Most of production tools are made by Ulyanovskiy Priboro-Remontniy Zavod to order. Production capacity of the shop is quite high – it can release up to 10 molds of moderate difficulty and about 15 dies per month. Production tools made by our company are reliable and serve the clients for many years.

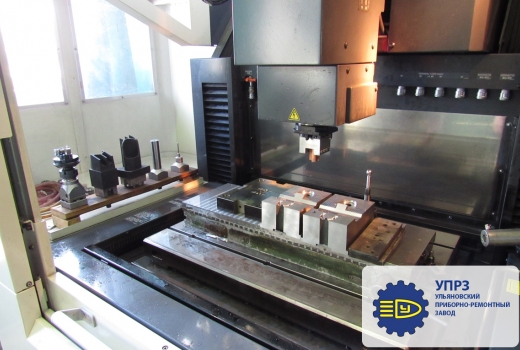

The equipment at the tool shop allows us to do the full cycle of producing dies and molds at each respective site, equipped with milling, filing, drilling, lathe, coordinate-filing and electroerosion equipment from both domestic and overseas producers.

Production sites of the tool shop

- Site for mechanical processing of parts of dies and molds using milling, lathe, drilling and other machines.

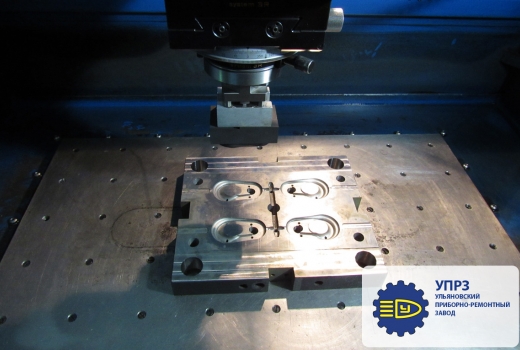

- Coordinate boring site. It is intended for boring of bearing plates and shaping parts.

- Site with coordinate filing machines and CNC mills. It is intended for filing the bores at particular coordinates and processing of parts of electrodes of shaping parts and molds using special programs.

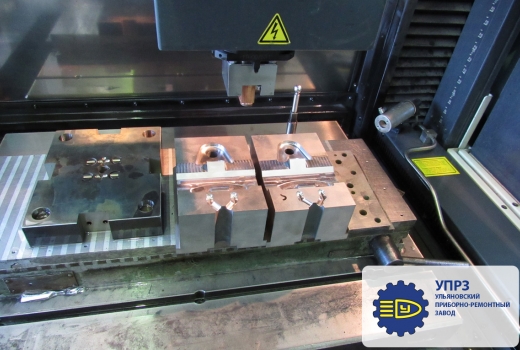

- Electroerosion machine site. This site is intended for processing of shaping parts via electrode burning with electrodes made of copper or graphite, and for wire cutting.

- Site for optical specialized grinding of profiles of shaping parts and electrodes.

- Site for fine-tuning and assembly of dies and pressing forms via various operations.

At the request of the client, Ulyanovskiy Priboro-Remontniy Zavod can do lettering of shaping parts of the products and marking them with laser. To produce shaping parts, we use both imported Boehler steel and domestic-made steel (У8А, ХВГ, 40Х13, У10А, 9ХС, 4Х5МФС, Х12 and others).

Tool shop also provides additional service: maintenance and repair of equipment and sharpening of cutting tools.