This kind of casting has gained ground recently. Castings produced by pressure casting are used in the manufacture of furniture, household appliances, automobile construction and many other industries. Such products are very durable, leakproof and have a good marketable condition. Equipment for pressure casting of metals and alloys is designed for hundreds of thousands, even millions of molding cycles, however, is rather difficult-to-make and expensive.

There are many types of pressure casting machines for the operation of said equipment, with production range constantly kept up to date. They are divided into casting machines with horizontal and vertical pressure chambers. Each of these types has its own series in size, capacity, design features and manufacturers.

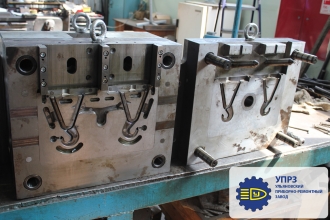

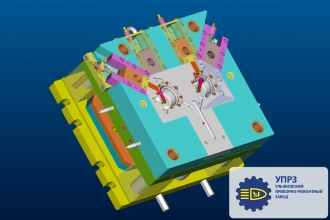

Our company has successfully performed the design, manufacture and commissioning of molds for metal casting of items used in mechanical engineering, as well as for manufacture of household appliances.

Molds for pressure casting of non-ferrous metals and alloys can have different degrees of complexity: with slides, hydraulic cylinders, inclined pushers, inserts, single-cavity, multiple cavity, multiple parting planes, etc. We have vital skills and equipment for the manufacture of tooling of any complexity. In most cases, we have opportunities for operation of said tooling on using in-house facilities.