Casting Quality Die Casting Pros Die Casting Cons

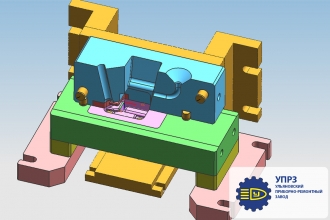

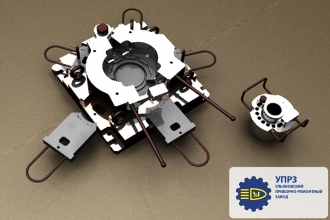

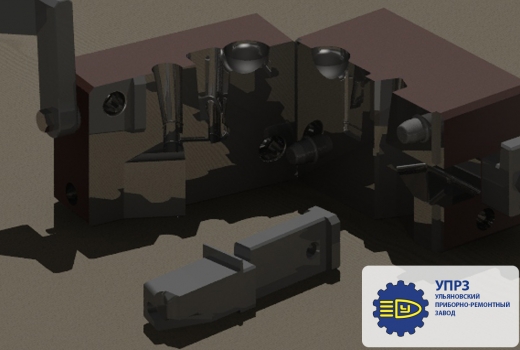

Die casting is carried out either by means of stationary chill molds or chill casting machines and machine tools. Chill molds can be simple and complex and consist of hydraulic cylinders, pushing system, core magazines, metal inserts. The manufacture of this type of equipment requires superior skills in engineering and tool-making facilities.

Die casting is a free pouring of molten metal in chill molds, metal molds (from French Coquille - shell, casing), followed by natural or artificial cooling.

The main components of the chill mold are plates, inserts, mold halves, cores, etc. They are usually made of steel or cast iron. Chill molds may have simple configuration, but in practice chill molds having very complex configuration are common.

Our company has all the necessary potential to design and manufacture chill molds of any complexity, including with subsequent reference to the customer's equipment. We have adequate productive capacity to manufacture chill molds not only of plain and heat-resistant steels, but also of cast iron. Custom-made equipment is most often tested by means of in-house equipment and facilities. We organize site visits of our specialists as part of the technical assistance in the start-up of equipment at the customer's facilities.

The very technical process of casting in the chill mold is not multi-operational. All operations are relatively simple and take little time, with duration of operations limited only by cooling of molding to the desired temperature. Most operations of the manufacturing cycle are mechanically and automatically controlled, which undoubtedly is a distinct advantage of this method. In addition, it is important that the permanent chill mold eliminates the need for dispensable molds, whose manufacturing process is rather costly and time-consuming.

Casting Quality and Molding Features

If we compare metal molds with sand ones, the former are characterized by much more essential characteristics: thermal conductivity, strength, heat capacity, very low gas permeability and generation capacity. Because of these material properties the chill mold exhibits the following features when reacting with metal:

- High-performance thermal interaction between the casting and mold (casting and alloy get cooled faster in the chill mold than in the sand mold);

- Chill mold prevents shrinkage to a greater degree, making it difficult to extract, but prevents deformation of the mold, thus reducing the likelihood of porosity. Thus, die cast products are more precise;

- Cast surface has higher quality due to minimal physicochemical interaction of casting metal with the mold (chill mold);

- Chill mold has low gas generation capacity and is nearly gas-tight, and the location of casting the chill mold, metal feed method and ventilation system can ensure air and gas output from the mold during casting.

Die casting performance is primarily affected by leveraging of advantages of chill casting production, thus it is necessary to consider all the features, strengths and weaknesses of this method (most often compared to sand mold casting) in the context of each individual production, which can be successfully carried out by a qualified specialist.

Die Casting Pros

- High quality casting and sustainable quality performance (accuracy, mechanical properties, density, texture, roughness).

- Comprehensive facilities to produce castings with complex internal configuration and outer surface through the use of disposable sand cores in the molds, if necessary.

- Increased (2-3 times) labor productivity due to absence of time-consuming operations, reduced costs for production facilities, equipment and treatment facilities.

- Absence of complicated and hazardous operations that results in reduced environmental pollution and better working conditions.

- Possibility of power-actuated and computer-aided die casting through the use of permanent chill molds. In addition, it is in chill mold production that it is possible to automatically adjust process parameters, which fundamentally changes the nature of the caster's work.

Die Casting Cons

- Rather costly chill mold, manufacturing complexity, with chill mold cost increasing as a proportion of complexity of casting configuration.

- Limitations in the mold resistance and total number of suitable castings. Chill mold life affects the overall cost effectiveness of the casting process, especially in the case of steel and cast iron casting.

- Limited capacity of obtaining thin-walled elongated castings due to high-intensity cooling of metal in the mold.

- Mold hardness can cause stresses and even cracks in castings when extracting.

- Irregular shape castings require the use of a great number of sand cores, which compromises the precision of castings.

Having compared the pros and cons of die casting, the specialist determines the efficiency of its use at a particular facility, because die casting is beneficial only in mass and batch manufacturing. However, it is die casting that can be attributed to low-operational, low-waste material and labor-saving process, which allows to improve working conditions and reduce the adverse environmental impact.